1. Understanding the Basics of a Smart Energy Meter

A smart energy meter is an advanced device that tracks the amount of electrical energy consumed in a building or by an electrical device. It provides real-time data and logs energy usage over time for further analysis. Smart energy meters often come equipped with communication systems that allow remote monitoring and data transmission to a central server.

Key Features of a Smart Energy Meter:

- Real-Time Energy Monitoring: Measures voltage, current, power factor, and energy consumption.

- Data Logging: Stores historical data on energy usage for analysis.

- Communication Capabilities: Supports wireless or wired communication for remote data access.

- User Interface: Displays energy consumption data to the user via LCD or LED displays.

2. Design Considerations for a Smart Energy Meter

Before you begin the design, consider the following requirements:

- Accuracy: High accuracy is essential for precise measurement of energy consumption. The meter should meet regulatory standards (e.g., IEC 62053-21 for Class 1 accuracy).

- Power Supply: Decide whether the meter will be powered by the mains or a separate power source, such as a battery.

- Data Logging Frequency: Define how often the energy meter logs data, which could range from every second to once a day, depending on the application.

- Communication Method: Choose the method of communication—wired (e.g., RS-485, Ethernet) or wireless (e.g., Zigbee, Wi-Fi, LoRaWAN).

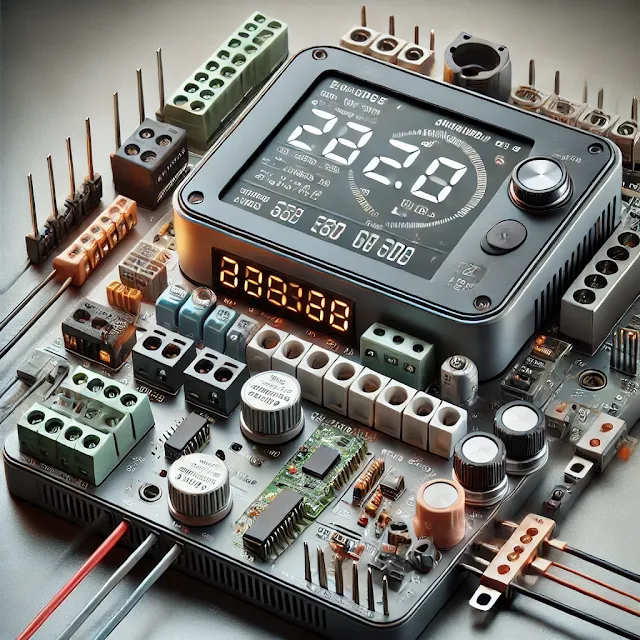

3. Selecting the Key Components

The key components of a smart energy meter include sensors, a microcontroller, a data logging module, a communication module, and a display. Below is an overview of the main components needed:

a. Current and Voltage Sensors

Current and voltage sensors are critical for measuring the electrical parameters of the energy system.

1. Current Sensors: Choose current transformers (CTs) or Hall-effect sensors to measure the current flowing through the circuit.

- Current Transformer: A non-invasive solution that clamps onto the wire and measures current by inducing a current proportional to the flow.

- Hall Effect Sensor: Measures the current by detecting the magnetic field generated by the flow of current in a conductor.

2. Voltage Sensors: These sensors measure the voltage in the system.

- Resistive Divider Circuit: A simple and cost-effective solution to scale down the mains voltage to safe levels that the microcontroller can process.

- Precision Voltage Sensors: For more accurate and isolated measurements.

b. Microcontroller

The microcontroller is the brain of the smart meter and is responsible for processing sensor data, managing communication, and storing data.

- Popular Choices: ESP32, STM32, and ATmega328P microcontrollers are widely used due to their low power consumption, sufficient processing power, and built-in communication interfaces.

- Key Features: Ensure the microcontroller has sufficient analog-to-digital converter (ADC) channels for sensor inputs, UART/SPI/I2C interfaces for communication modules, and enough storage or external memory support for data logging.

c. Energy Measurement IC

Dedicated energy measurement ICs simplify the design by handling the complex calculations of energy parameters like power factor, active/reactive power, and energy.

- Examples: Analog Devices ADE7753 or Cirrus Logic CS5463 are popular ICs that handle accurate energy calculations, reducing the computational load on the microcontroller.

d. Data Logging Module

The data logging module stores historical data for future analysis. This can be done using:

- SD Card Module: Affordable and provides ample storage. However, it requires periodic access for data retrieval.

- Flash Memory: Compact and efficient for continuous data logging.

- EEPROM: Suitable for logging small amounts of data over time but has limited write cycles.

The data logging frequency and the storage method should be chosen based on the application and available memory.

e. Communication Module

A communication module allows for data transmission to a remote server or cloud platform. There are various options depending on the application:

- Wi-Fi (ESP8266/ESP32): Ideal for home automation systems where the meter can connect to an existing Wi-Fi network.

- LoRaWAN: Suitable for long-range communication with low power consumption.

- Zigbee: Ideal for smart home networks with multiple connected devices.

- GSM/4G Modules: Suitable for systems in remote areas where cellular communication is the best option.

f. Display Module

A user-friendly display is essential for providing real-time feedback on energy usage. Options include:

- LCD Displays: Cost-effective and widely used in simple energy meters.

- OLED Displays: Offer better visibility and energy efficiency, suitable for more advanced designs.

4. Circuit Design

a. Sensing Circuit

The first step in designing the circuit is connecting the current and voltage sensors. The outputs of these sensors are fed into the ADC pins of the microcontroller or a dedicated energy metering IC.

- Current Transformer: The CT’s secondary winding generates a small current that is typically converted into a voltage signal using a burden resistor. This voltage signal is then fed into the ADC.

- Voltage Divider Circuit: This scales down the mains voltage to safe levels and is input to the ADC.

b. Microcontroller and Energy IC Interface

The microcontroller processes the voltage and current signals to calculate energy parameters like real power, apparent power, and power factor. Alternatively, this can be done by a dedicated energy measurement IC like ADE7753, which sends processed data to the microcontroller via SPI or I2C communication.

c. Data Logging Circuit

Connect the chosen data storage module (e.g., SD card or EEPROM) to the microcontroller. The data logging frequency will determine how much data is written to the storage device over time. Use a file system (e.g., FAT32 for SD cards) to organize data efficiently.

d. Communication Circuit

The communication module (e.g., Wi-Fi, LoRa) connects to the microcontroller via UART, SPI, or I2C interfaces. For wireless communication, ensure the antenna placement is optimized to avoid interference and maximize range.

e. Power Supply Circuit

Design the power supply circuit to ensure that all components, including sensors, microcontroller, communication modules, and display, receive stable voltage. This can be achieved with buck converters or linear regulators to step down from the mains supply to the required levels (e.g., 3.3V or 5V).

5. Programming and Calibration

a. Energy Measurement Algorithms

If using a microcontroller for energy calculations, you need to implement algorithms to compute parameters like active power, reactive power, power factor, and energy. Use sampling techniques to capture voltage and current waveforms and calculate root mean square (RMS) values.

- Power Calculation: Power is calculated using the formula: Where and are the RMS values of voltage and current, and is the phase difference between them.

b. Calibration

Accurate energy measurement requires calibration of the sensors and metering ICs. Calibration involves applying known voltage and current levels to the meter and adjusting the system until the measurements match the known values.

- Zero Offset Calibration: Remove any sensor offset when no current or voltage is applied.

- Gain Calibration: Adjust the gain factor for accurate readings across different ranges of current and voltage.

6. Implementing Data Logging

Program the microcontroller to periodically log energy data to the storage module. Depending on the application, data can be logged at intervals of seconds, minutes, or hours. For each logging cycle, store parameters such as:

- Voltage

- Current

- Power Factor

- Active Power

- Energy Consumption

Use timestamping to record the time and date for each data entry.

Data Retrieval

To access the data, provide options like:

- Local Access: Retrieve data from the SD card manually or via USB.

- Remote Access: Send the data to a cloud platform for remote monitoring.

7. Testing and Troubleshooting

Once the design is complete, test the smart energy meter in real-world conditions. Check for accuracy and reliability under different load conditions. Pay attention to the following:

- Sensor Accuracy: Verify that the sensors accurately measure voltage and current.

- Data Logging Reliability: Ensure that data is logged consistently and that no data corruption occurs.

- Communication Stability: Test the reliability of the communication system, especially in challenging conditions (e.g., weak Wi-Fi signals).

8. Final Thoughts

Designing a smart energy meter with data logging requires careful consideration of sensor accuracy, power management, data storage, and communication. By following the steps outlined above, you can create a robust system that not only measures energy consumption accurately but also logs data for analysis and optimization. Smart energy meters offer significant benefits, including energy savings, better management of electrical systems, and real-time monitoring capabilities that can lead to improved energy efficiency across residential and industrial applications.